Ports

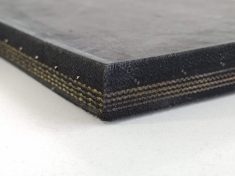

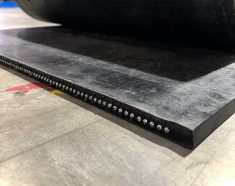

Gummilabor rubber belts can be used for bulk material handling within ports, to load or unload materials from ships. The efficiency and safety of these operations depend on the ability to transport these materials quickly and securely, minimizing the risks of loss or damage to the products.In this context, Gummilabor rubber belts prove essential in ensuring a continuous flow of materials between ships and port terminals, optimizing handling times and increasing port productivity. These belts are designed to withstand tough working conditions, such as exposure to weather elements, salt corrosion, and wear from handling abrasive and heavy materials. Their durability and resistance ensure high performance even during large-scale loading and unloading operations, minimizing downtime and maintenance costs.

Since ports handle large volumes of materials, the use of rubber belts facilitates the automated management of material flows, reducing the need for manual handling and, consequently, lowering the risk of worker injuries. Their versatility allows them to adapt to various types of materials and ensures a more sustainable management of resources, contributing to the continuity and efficiency of the logistical process within the port.