Chemical Industry

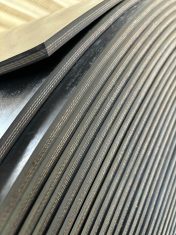

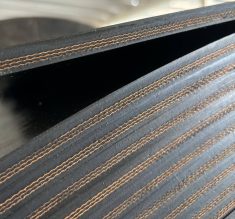

The chemical industrial sector is focused on the production of chemical compounds, starting from raw materials such as oil and natural gas, which are then used by secondary industries as a starting point for further transformations.In the overall production process of the chemical industry, material handling plays a crucial role in ensuring efficiency, safety, and operational continuity. In this context, Gummilabor rubber belts represent an essential solution for transporting raw materials, semi-finished products, and finished goods within chemical plants. These belts are designed to withstand extreme working conditions, such as exposure to corrosive substances, high temperatures, and environments with a high risk of contamination.

Thanks to their high wear resistance, flexibility, and durability, rubber belts optimize transport processes, reducing the risk of material dispersion and enhancing workplace safety. Additionally, their use helps increase plant productivity by reducing machine downtime and maintenance costs.

Finally, the selection of suitable Gummilabor rubber belts also contributes to the sustainability of the chemical industry by minimizing waste and ensuring more efficient resource management. For this reason, rubber belts are a strategic element within chemical plants, supporting the functioning of the entire sector and its ongoing technological innovations.