Wood Industry

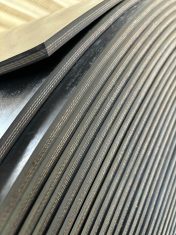

The wood industry is the sector that deals with all the various processing stages of wood, a natural and versatile material used in numerous fields. The wood processing process includes several stages, such as cutting, planing, sanding, painting, and assembly.Gummilabor rubber belts play a crucial role in the transportation of wood throughout the production process. During the initial stages, such as cutting and planing, the rubber belts are used to move logs or pieces of wood from one machine to another, ensuring that the workflow is continuous and uninterrupted. Additionally, rubber belts are also employed to transport wood waste, such as wood chips and sawdust, which are separated during the manufacturing process. Thanks to their durability and flexibility, these belts can operate in industrial environments with the presence of dust and debris without compromising process efficiency.